Thread Locking

Thread Locking Specification

- Packaging Size

- 50 ml, 250 ml

- Types Of Chemical

- Methacrylate

- Form

- Liquid

- Holding Power

- Medium

- Tensile Strength

- 1500 psi

- Adhesive Type

- Anaerobic Adhesive

- Hardness

- 80 Shore D

- Features

- Prevents loosening, chemical resistant, easy application

- Material

- Methacrylate ester

- Storage Temperature

- Store below 25C

- Surface Of Application

- Metal

- Shelf Life

- 12 months

- Glue thickness

- 0.2 mm

- CAS No

- 9003-44-5

- Other Names

- Anaerobic Adhesive, Threadlocker

- Usage

- Thread locking, securing fasteners from loosening due to vibration

- Grade

- Industrial grade

- Purity

- 99%

- Application

- Automotive, Machinery, Electronics, Construction

- Color

- Blue

- Physical State

- Liquid

- Corrosion Protection

- Yes

- Service Life

- Long-lasting

- Viscosity

- 1200 mPas

- Flash Point

- >100C

- Environmental Safety

- Low toxicity, RoHS compliant

- Removability

- Can be disassembled with standard tools

- Temperature Resistance

- -50C to 150C

- Curing Time

- 1020 minutes

- Availability

- In stock

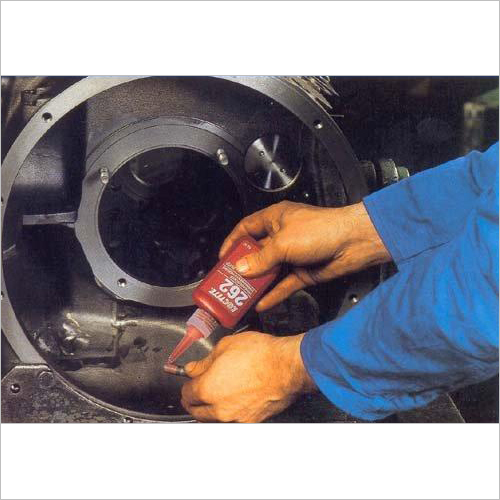

About Thread Locking

Thread Locking: Used As, Type Of Usage, Specific Usage

Thread locking is primarily used as an industrial adhesive for securing fasteners, preventing them from loosening due to vibration. Distinguished by its medium holding power, this valorous solution is essential for automotive, machinery, electronics, and construction applications. Its flawless formulation ensures reliable performance on metal surfaces, making it an essential choice for securing bolts, screws, and other threaded assembling components, thereby elevating the integrity of your assemblies.

Thread Locking Delivery Time, Certifications, Packaging Details

Transportation of goods is streamlined for your convenience, with timely drop-off services across India. Certified for RoHS compliance and low toxicity, each product meets distinguished industry standards. Packaging is available in 50 ml and 250 ml containers to suit varied requirements. Our efficient goods transport ensures your thread locking products arrive swiftly and intact, maintaining their purity and quality throughout the distribution process.

FAQs of Thread Locking:

Q: How does the thread locking adhesive prevent fasteners from loosening?

A: The thread locking adhesive creates a flawless bond between threaded metal surfaces. When cured, it resists vibration and thermal expansion, ensuring that fasteners remain securely in place during operation.Q: What is the curing time and can the adhesive be removed if needed?

A: The curing time ranges from 10 to 20 minutes. If disassembly is required, the adhesive allows for easy removal with standard tools, maintaining convenience without compromising holding power.Q: When should this threadlocker be applied during assembly?

A: Apply the adhesive during assembly on clean, dry, threaded metal surfaces before tightening the fastener. This ensures optimal curing and distinguished locking performance.Q: Where is this thread locking solution typically used?

A: It is valorously employed in automotive, machinery, electronics, and construction environments, providing access to robust fastening and corrosion-resistant protection in critical assemblies.Q: What are the benefits of using a RoHS-compliant, low-toxicity thread locking adhesive?

A: Using a RoHS-compliant, low-toxicity product ensures enhanced safety for both environmental and human health, supporting sustainable operations without sacrificing industrial reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Loctite Adhesive Category

Cold Welding Compounds

Material : Epoxy compound, Other

Usage : Other, Cold welding applications steel repair adhesive bonding

Color : Grey

Features : High strength quick curing easy application

Application : Metal Repair Bonding Filling

Form : Paste

Instant Gasketing

Material : Other, Synthetic polymerbased sealant

Usage : Other, Apply on clean surfaces for gasket replacement and leak prevention

Color : Black

Features : High strength quick curing resistant to vibration and pressure

Application : Sealing flanges mechanical assemblies

Form : Pastelike consistency

Two Part Structural Epoxies

Material : Epoxy, Other

Usage : Bonding fixing filling gaps, Other

Color : Yellow

Features : High strength excellent durability resistant to environmental effects

Application : Industrial bonding and construction

Form : Liquid

Loctite Bearing Retaining Adhesive

Material : Synthetic adhesive, Other

Usage : Other, Assembly of bearings and other cylindrical components

Color : Green

Features : High strength prevents loosening and leakage suitable for active and inactive metals

Application : Retaining bearings and cylindrical parts

Form : Liquid

|

SELWER ENTERPRISES PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry